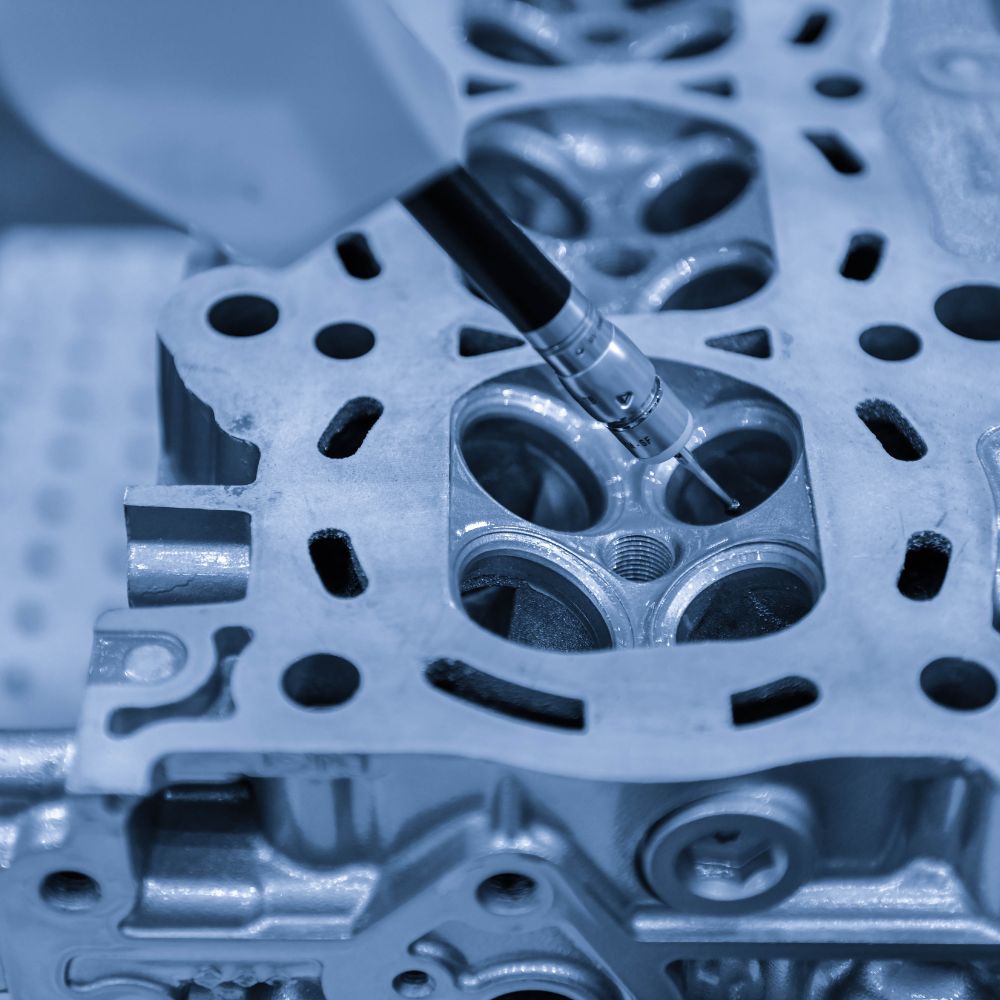

Within the manufacturing course of often called aluminum die casting, molten aluminum is injected right into a metal mould cavity whereas the mould cavity is beneath excessive strain. This method is acknowledged for its excessive effectivity and widespread software. Using this method ends in the manufacturing of sophisticated, high-quality items that possess exceptional dimensional precision and floor end. Aluminium die casting has grow to be the popular technique for the manufacturing of all kinds of elements throughout quite a lot of industries, together with the automotive business, aerospace business, electronics business, and plenty of others. This is because of the truth that it’s recognized for its versatility and cost-effectiveness.

Step one within the strategy of die casting aluminum entails melting aluminum ingots at temperatures which might be larger than 650 levels Celsius (1200 levels Fahrenheit). After the molten aluminum has reached the specified consistency, it’s poured right into a metal mould cavity utilizing high-pressure equipment as rapidly as doable. By making use of this strain, the molten steel is ready to successfully fill each intricate aspect of the mould, which in the end ends in a reproduction that’s exact and correct in its illustration of the specified part.

Aluminum die casting is a manufacturing technique that’s really useful because of its a number of advantages, which make it a well-liked alternative. The potential of the fabric to supply intricate geometries and sophisticated objects with tight tolerances is a major benefit of the fabric. Moreover, the high-pressure injection method results in a better floor polish, which ceaselessly allows a discount within the requirement for additional ending procedures. As well as, aluminum is extremely valued for its light-weight but sturdy qualities, which makes die-cast aluminum components particularly enticing in functions the place weight discount is of utmost significance, resembling within the aerospace and automotive industries.

Die casting in aluminum has a variety of functions which might be each complete and diversified. Aluminum die casting is a vital course of that’s utilized in all kinds of sectors. It’s sometimes used to fabricate housings for digital devices and complicated aeronautical elements, in addition to engine elements and transmission components for cars. The potential of this manufacturing course of to fabricate components of superior high quality, at a cheap worth, and with excellent mechanical qualities has solidified its place because the manufacturing technique of alternative for companies that need to obtain precision and effectivity of their manufacturing processes.

As per the newest analysis carried out by Verified Market Analysis specialists, the International Aluminum Die Casting Market exhibits that the market might be rising at a quicker tempo. To know extra development elements, obtain a pattern report.

High 5 aluminum die casting corporations crafting excellence with precision

Alcoa Company, previously often called Aluminum Firm of America, is a worldwide chief in aluminum manufacturing and innovation. Based in 1888 by Charles Martin Corridor, Alcoa has its headquarters in Pittsburgh, Pennsylvania, USA. The corporate focuses on aluminum manufacturing for numerous industries, together with aerospace, automotive, and packaging.

Ryobi Restricted is a Japanese producer of energy instruments, printing gear, and builders’ {hardware}. Established in 1943, Ryobi has its headquarters in Fuchu, Hiroshima, Japan. The corporate is thought for its high-quality and revolutionary energy instruments, catering to each DIY fanatics and professionals within the building and woodworking industries.

Aluminum Company of China Restricted

Aluminum Company of China Restricted (Chalco) is a number one producer of aluminum and alumina, headquartered in Beijing, China. Based in 2001, Chalco is likely one of the world’s largest producers of those supplies, serving numerous industries together with transportation, building, and packaging. The corporate is thought for its dedication to sustainable practices in aluminum manufacturing.

Rio Tinto is a multinational mining company headquartered in London, United Kingdom, with a major presence in Australia, Canada, and different areas. Based in 1873, Rio Tinto specializes within the extraction and processing of metals and minerals, together with aluminum, copper, diamonds, and iron ore. The corporate is likely one of the largest mining firms globally, with operations spanning throughout numerous continents. Rio Tinto is acknowledged for its dedication to sustainable mining practices and neighborhood engagement.

United Firm Rusal is likely one of the world’s largest aluminum producers, headquartered in Moscow, Russia. Based in 2007, Rusal has a major world presence with operations in Russia, Guinea, and different nations. The corporate specializes within the manufacturing of aluminum and alumina, catering to industries resembling transportation, building, and packaging. Rusal is thought for its revolutionary strategy to aluminum manufacturing and dedication to sustainability.